Automating PCR prep. on flowbot® ONE

The preferred solution

Many PCR worklows implement automation to achieve greater accuracy, higher throughput, avoid contamination, lessen human errors, and free up their lab technicians.

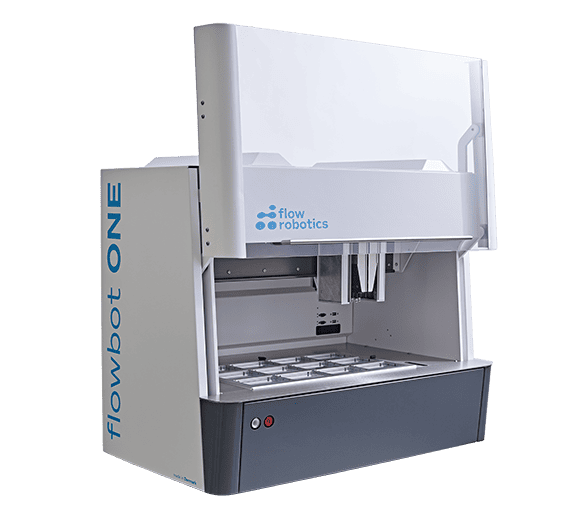

For those wishing for a user-friendly and agile system, flowbot® ONE has become a preferred solution.

With many unique features to optimize the different steps in a PCR protocol, flowbot® ONE enables effective and safe lab processes when preparing your PCR samples for amplification in a thermal cycler.

The guided user interface allows you to choose the features you want with a single click as you set up your program.

Let’s take a closer look.

Serial dilutions & Normalization

By normalizing or diluting samples, you can ensure that each reaction starts with a known and consistent amount of template DNA or RNA.

Normalization to a specific concentration or dilution factor can standardize the input for all samples, making the results more meaningful and comparable.

To optimize and simplify this process, the flowbot® ONE carries a pre-programmed template and the software features “reuse tips” and “prewetting and mixing”.

Reagent Dispensing

While reagent dispensing is typically a simple liquid transferring step, it is also an error-prone and time-consuming process.

However, the accuracy of flowbot® ONE ensures consistent and precise volumes across multiple samples – giving correct results and highly reproducible experiments with minimum effort.

To keep temperature sensitive reagents in optimal conditions, flowbot® ONE has an integrated coldplate.

Simply place it anywhere on the deck and drag and drop it in the software.

Sample Preparation

Once the master mix is ready, you can add your samples to the PCR reaction plates.

The flowbot® ONE has a wide range of features to make this process as secure and accurate as possible, such as “liquid level detection”, “prewetting and mixing”, and “bottom touch”.

Master Mix Preparation

With the reagents in place, flowbot® ONE is ready for your master mixes. Dispensing the master mixes evenly across a PCR 96- or 384 well plate is optimized with the flowbot® ONE software feature “contact aspiration”.

Sample Tracking

Having a good data tracking process is crucial to avoiding sample misplacements and other human errors. With an often overwhelming number of samples, this is one of the most error-prone parts of if performed manually.

Automating with a liquid handler that has a good tracking solution will undoubtedly help reduce these errors.

The flowbot® ONE, for example, has its own sample tracking solution, ScanID. ScanID can scan an entire rack in seconds and, subsequently, send the data to the flowbot® ONE software for further processing with full traceability through the entire workflow.

It also acts as an error control by letting you know if you’ve scanned the same sample multiple times.

Manual vs. Automated pipetting

Now that you know how flowbot® ONE can optimize the process, let’s take a look at some results demonstrated in the application note, “Simplify PCR setup with flowbot® ONE”.

To show how much time you’ll save when automating liquid handling with flowbot® ONE, we ran and timed a PCR program.

In the protocol, Genomic Escherichia coli DNA was diluted to eight different concentrations for use with the reaction template, and two independent master mixes were prepared using two different ready mixes.

The flowbot® ONE was programmed to assemble each master mix by initially pipetting the reaction components into an empty tube. From there, the flowbot® ONE transferred the master mix to an 8-tube PCR strip before distributing it into the 96 well PCR plate.

The reaction mix was subsequently completed with the addition of the template DNA to the appropriate PCR plate wells.

Running 96 samples on flowbot® ONE took 41 minutes 8 seconds. An equivalent manual setup took 1 hour 8 minutes to complete. That means you’ll save 27 minutes per plate.

But you get much more in addition to those 27 minutes.

You get much less hands-on time. And you can use the time that flowbot® ONE is working on other tasks, such as analysis or preparing the next batch.

Want to learn more?

Get in touch with one of our specialists to see how it can figure into your PCR workflow.

Talk to a specialist

Fill in the form and we’ll be in touch: