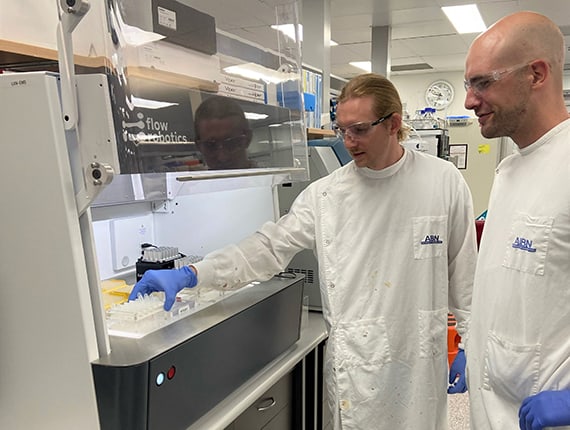

The Australian Institute for Bioengineering and Nanotechnology at UQ is working on a project that aims at building a microbial strain factory in collaboration with Queensland’s government. The project will implement a pipeline for the screening of microbial strains in an instrumental reactor system, and group is using flowbot® ONE for reducing the manual workload of such a huge undertaking.

Our goal is to characterize microbial strains for production of high-value compounds. We must do a characterization of a large number of strains to identify the key bottlenecks in the bioproduction of those molecules. That includes many pipetting tasks which was tedious and hard on my hands prior to implementing the flowbot® ONE

What for see how we can help you automate

Book a free demo and let’s talk, just fill in the form below

Contributing in better ways

Over the course of the last 3 years, the research group has tested and analyzed over 200 strains in reactors, which meant processing a huge number of samples.

Previously, it would take Dr Axa Gonzalez Garcia, who is the primary user of flowbot® ONE, up to 2 hours to do one fermentation run with 100 samples, where he only had to transfer liquid from the sample tubes to the sample vials.

“The flowbot® ONE does the job in 45 minutes, and in addition I am able to do other things simultaneously and contribute to the project in better ways. Since flowbot® ONE allows me to work non-stop, I increased productivity by 20 percent. That 20 percent extra time is of huge value to the team,” he says and adds that it means a lot to him, as a researcher, to contribute with more valuable work than manual pipetting.

Aside from the freedom that the flowbot® ONE provides, Dr Axa Gonzalez Garcia appreciates the versatility and adaptability of the robot and how easy it fits into his daily routine.

We chose flowbot® ONE because of the versatility, the number of components you can have on the deck as well as how easily we can change them around. We also chose it because it can hold both a hotplate and a coldplate. We tested other instruments, but we could quickly see a higher return on investment with the flowbot® ONE because of the parts that are available.

Instrumental for reaching deadlines

As with any major research project, the group must reach a tight deadline and there is no room for errors. This is where automated solutions make an instrumental difference.

“We automated to avoid errors and save time because we need to spend as much time as possible on carrying out experiments,” Dr Axa Gonzalez Garcia says and confirms that automation is a sensible investment in that regards.

As the group continue their work for designing improved yeast strains, the robot will continue to carry the heavy manual workload and help them reach their deadline.

About the Australian Institute for Bioengineering and Nanotechnology

The University of Queensland’s Australian Institute for Bioengineering and Nanotechnology (AIBN) is an integrated multi-disciplinary research institute bringing together the skills of world-class researchers in the areas of bioengineering and nanotechnology.

Founded in 2002, it is home to 18 research groups working at the interface of the biological, chemical, and physical science to alleviate current problems in human health and environmental issues in close collaboration with industry.

Get a free demo - no strings attached

Fill in the form and let’s talk