INTEGRATE & AUTOMATE WITH flowbot® ONE

The robot has an open API that makes it very simple to integrate instruments like robotic arms.

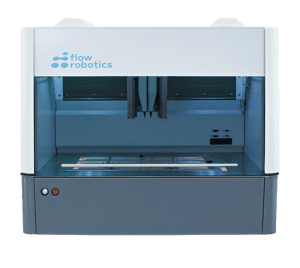

The flowbot® ONE is designed to serve two different roles:

- To be a stand-alone table-top unit

- To work smoothly as part of an integration.

Through collaborations with Automata and Peak Analysis and Automation, we offer end-to-end automation solutions – making the flowbot® ONE even less dependent on human interaction.

Peak Analysis and Automation

flowbot® ONE can be controlled from PAA’s innovative platform-independent S-RUN software package. With S-RUN you can link the flowbot® ONE to a range of other devices including:

- KX2 collaborative robot

- Plate sealer/de-sealer

- Plate readers & imagers

- Plate stacks, racks & incubators

- Plate washers & bulk reagent dispensers

Get the PAA Integration Sheet on flowbot® ONE

PAA has made an Integration Sheet with flowbot® ONE

Please fill in the form to get the sheet

Automata

You can integrate the flowbot® ONE into Automata’s LINQ bench system which is a fully automated platform. The platform comes with a collaborative arm that moves plates to and from the flowbot® ONE and other instruments on the workbench.

The flowbot® ONE is great because it gives us a lot of flexibility and is easily integrated with existing equipment. It makes it possible to accurately pipette the right amount of liquid into the well-plates that are loaded by our robot arm.

Uppsala University brings integration into the classroom.

Uppsala University is among our customers who are using flowbot® ONE in a fully automated workflow.

They have made an integration with a robot arm and software of their own designs as well as a digital microscope.

The flowbot® ONE was definitely the easiest instrument to integrate because of its very simple API. It works flawlessly in collaboration with a robot arm, partly because it’s so spacious which enables the instruments to work in parallel without colliding. Its super high precision also helps us with the millimeter-scale moves that are required.

Looking for integrations?

Book a meeting with one of our automation experts