Dr. Reddy's Laboratories

Accelerating Enzyme Screening Workflows

An easy solution for complex pipetting

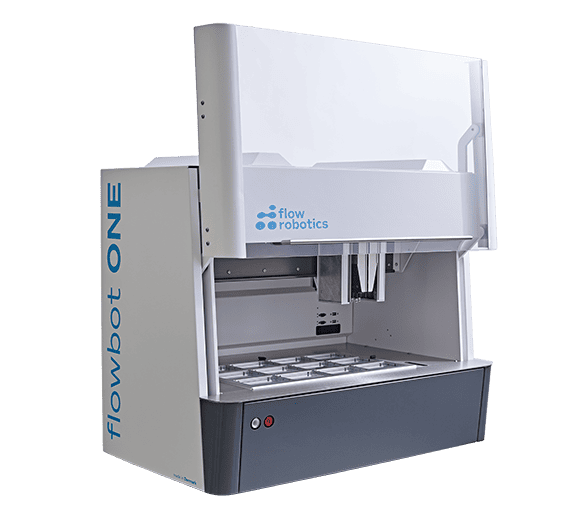

At Dr. Reddy’s Laboratories in Cambridge, UK, the flowbot® ONE provides liquid handling assistance in a wide range of applications. Most prominently, perhaps, is the preparation of enzyme screening plates and the work-up of biotransformation reactions including liquid movements during reaction quenching and sample transfer to analytical plates or vials.

Screening plates for every class of enzyme have been created using the flowbot® ONE and the use of the flowbot® ONE enables Dr. Reddy’s to efficiently screen a much higher number of projects than previously, by hand alone. This is done by creating a standard protocol for taking stock solutions of, for example, commercial and in-house enzyme powders hydrated in buffer and then dispensing them into individual wells typically of a 1.2 or 2.2 mL 96-well plate.

“Overall the flowbot® ONE transfers an enzyme into each well and then adds a substrate to these wells. The screening plate is then placed in a shaking incubator to allow for the enzymatic reaction before it is returned to the robot to sample from each of the 96 wells and to create a quench plate in a ‘stop solution’ suitable for the subsequent analytical technique used (LC, GC or UV)” explains Dr. Matthew Bycroft, Head of Biocatalysis, who oversees the enzyme screening projects.

Thus, the protocol can have several different liquids and solely based on the creation of eight 96-well enzyme screening plates can involve almost 1000 individual pipetting moves. While this can be done manually, it is time consuming and very prone to errors.

“We often deal with more than 200 samples per project. When we did it by hand it could take weeks’ worth of work just to create the screening plate, and then we would have to carry out the testing and analysis. With the robot, we save an incredible amount of time, and we know exactly what we add to every specific well. Typical plate generation can take less than a single day. The time during which the flowbot® ONE is working allows me to do other laboratory work, such as preparing reagents for the enzyme screen. So the overall plate creation, testing and analysis can be done easily within 1 week” says Dr. Camille Assaf, Biocatalysis scientist, the primary user of the flowbot® ONE.

With flowbot® ONE we can avoid errors such as sample misplacements and inaccuracies. When we previously created a full 96-well plate by hand it often became a challenge to find the right wells and could be difficult to remember the state of each well.

The key to a zero-error workflow

Anyone who works in a laboratory will know that an error-prone protocol can be quite stressful and it can be challenging to keep focus on counting wells throughout an entire day.

“With flowbot® ONE we can avoid errors such as sample misplacements and inaccuracies. When we previously created a full 96-well plate by hand it often became a challenge to find the right wells and could be difficult to remember the state of each well,” Dr. Camille Assaf explains.

Another error that can be avoided with automation is contamination: “In some of our work to create either microbial cell-banks or screening plates from live microorganisms it is very important that you can work in a sterile environment to avoid the risk of contamination. Our flowbot® ONE has both UV light and a HEPA filter which allows us to do manipulations in the right conditions and reduce the risk of contamination” says Dr. Matthew Bycroft.

The overall plate creation, testing and analysis can be done easily within 1 week.

The simplicity and flexibility of the flowbot® ONE makes us confident about bringing it into the future of our lab operations.

Getting the most out of samples

Dr. Reddy’s Laboratories work with very special tubes that do not fit into any standard existing racks. To help them automate their liquid handling as easily as possible, they got customized racks from Flow Robotics, in assistance with Appleton Woods, Flow Robotics’ distributors in the UK.

“The racks were made specifically for us which was amazing. Inputting customized racks into the flowbot® ONE is really easy. Either it is done through an application by Flow Robotics or we can do it ourselves by entering the new parameters into a template. All in all, it worked very well, and we could implement a liquid handler without too much change to our existing workflow,” says Dr. Camille Assaf.

Most of the materials that Dr. Reddy’s Laboratories work are of high value. That is why having low dead volumes is key to getting a high return on investment.

Flowbot® ONE has a number of unique software features that can help with that. At Dr. Reddy’s Laboratories, they are particularly happy about its automatic liquid level detection.

“We use liquid level detection which is great if we have a very expensive or precious solution that we are dispensing. Liquid level detection allows us to maximize amount of enzyme, or substrate; using as much of it as possible, and thereby avoiding losses with unused reagents. We also get high quality of data from screening with the flowbot® ONE: we are much more confident with the volumes and amounts transferred and the exclusion of any manual pipetting means that there is no human error. The flowbot® ONE can also pipette smaller volumes over multiple plates into individually selected wells more accurately than in manual work,” Dr. Camille Assaf points out.

“There are lots more projects that we can undertake now that we have the flowbot® ONE because of the various manipulations involved; now we have the robot and projects are starting to snowball. We look forward to finding new applications for the robot in the future outside of the area of biocatalysis and enzyme screening, and other members on site (in chemistry and analytical disciplines) are considering applications using the flowbot® ONE given our success in the few months we have had the robot. The simplicity and flexibility of the flowbot® ONE makes us confident about bringing it into the future of our lab operations.”

Want to see if flowbot® ONE can help you?

Just book a demo – no strings attached

About Dr. Reddy’s Laboratories (EU) Ltd.

Dr. Reddy’s Laboratories Ltd., is an integrated global pharmaceutical company committed to providing affordable and innovative medicines for healthier lives, with a commercial presence in more than 70 countries and 25,000 employees worldwide.

Dr. Reddy’s Laboratories (EU) Ltd., Cambridge, UK, is a specialist R&D technology centre that focuses on developing technical solutions for the production of highly complex Active Pharmaceutical Ingredients (APIs) and drug intermediates. With a history in world-leading asymmetric chemo- and bio-catalysis together with expertise in organic synthesis and continuous processing, coupled with high quality analytical support, Dr. Reddy’s Laboratories (EU) Ltd., develop cleaner, quicker and more efficient routes to these complex molecules.